- Get link

- X

- Other Apps

The average price for Concrete Forms ranges from 10 to 400. Large slabs solid and lightened inclined drop beams infillings column heads cantilever beams etc.

4 1 Formwork For Concrete Slab

Concrete Expansion Joint in Grey with 29 reviews.

Concrete slab forms. Fortunately modern concrete contractors have come up with just the tool to make creating curved concrete surfaces a breeze a flexible plastic form system. Most of the concrete slabs we pour are 6 thick. Slab formwork comes in varying types.

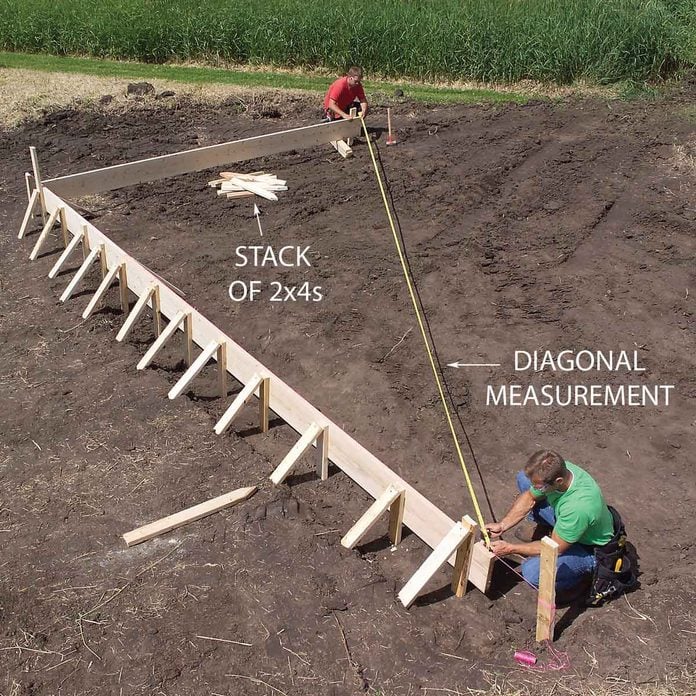

Concrete Slab Formwork Complete range of slab formwork products to cover applications such as. After all a standard concrete form can only make square-shaped slabs. The string will act as a guide to keep the form boards straight.

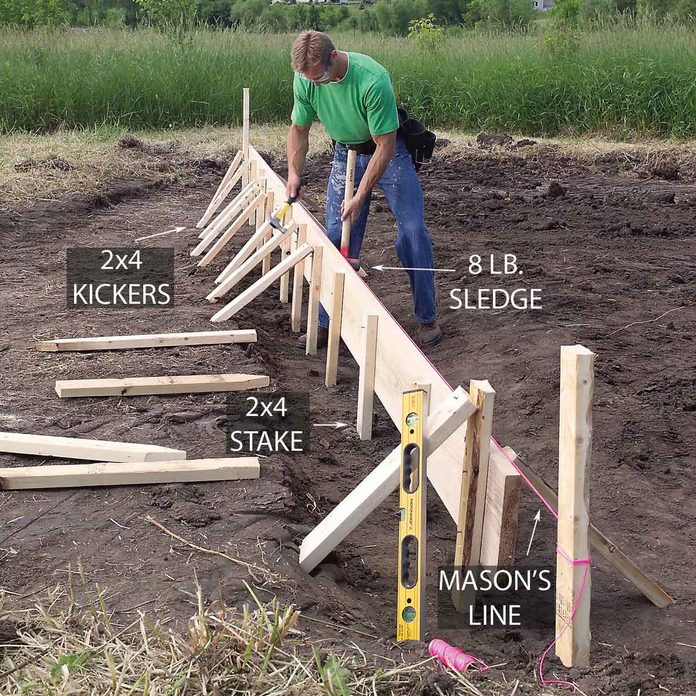

Several methods of concrete construction are used to showcase the owners technical ability. Excellent concrete finishes and great safety features for. Place 2x4 stakes and 2x4 kickers every two feet along the form boards for support.

In essence these systems consist of specialized plastic lengths that can be positioned into non-linear forms. Get Instant Quality Info at iZito Now. This article will refer to a slab form wall forms have completely different requirements.

Every concrete slab should have a minimum slope of 18-in. Concreteshedslab concreteslabforshed mikedayconcreteIn this video Im going to show you how to form pour and finish a concrete slab for a shed. The only other additional materials needed are.

We use 2x6s for most residential applications. Sometimes all four sides arent exactly the same length a 30 ft. Some of the most reviewed products in Concrete Forms are the SQUARE FOOT 22 in.

Theres modular formwork that is made for solid or lightened slabs. Mono Slab EZ Form allows you to save time labor and money and providing a far superior process compared to traditional methods. Ad Get Slab Concrete.

If youre thinking of installing a concrete slab for a house garage or shed and want to try and tackle it yourself Ill teach. Freshly poured concrete can push form boards outward leaving your slab with a curved edge thats almost impossible to fix. Insulated Concrete Forms ICFs An insulated concrete form system consists of a hollow block of insulating materials that fit together and is filled with concrete and further reinforced with steel.

We do apologize for the audio quailty as we forgot our mic. Is forming a 30 x 28 x 6 concrete slab for a garageIll sho. If someone is building a house or a commercial garage we thicken the edges to 12.

ICF systems are constructed using a foundation slab and the system remains in place to become the foundation and the exterior wall system. Wood forms for concrete slabs The most basic forms for concrete slabs where the concrete will not exceed 6 inches in height consist of wooden. Forming a concrete slab is really quite easy if you have a plan to go by.

Building a straight form for concrete is fairly simple as long as the correct techniques are used. The best way to avoid this is with extra strong bracing. Set the forms at the proper height before bringing in the last lift.

This video will teach you how to form a concrete slabMy company Days Concrete Floors Inc. Mono Slab EZ Form is a patented product that insulates and forms in the same step. Plastic Concrete Footing Form with 90 reviews and the Trim-A-Slab 12 in.

That way you can use the forms themselves as a guide for the final base height. Timber beam formworks on the other hand are easier to assemble and adapt to different slab geometries. Forming the edges of a slab is very important.

The depth and width of the concrete placement determine the bracing and forming material required. Similarly there are other forms of slab formwork ranging from waffles to aluminium forms for concrete slabs. We use 2x12s to form the edges when they are thicker.

Experience the MSB Form. In this video we show you the basic and fundamentals of forming concrete for a driveway addition. Get Instant Quality Info at iZito Now.

Including post-tensioning roof and floor slabs full height thermally broken and insulated sandwich walls form liner and board formed textured walls integrally colored stamped and polished concrete flooring and traditional reinforced concrete. What is the price range for Concrete Forms. It takes us about a half hour to form a concrete slab this size.

The set-up is simple. Ad Get Slab Concrete. If youre forming a garage slab or a house slab the steps are basically the same.

How To Build A Straight Form For Concrete 6 Steps With Pictures

How To Build A Straight Form For Concrete 6 Steps With Pictures

File Concrete Slab Forms Jpg Wikimedia Commons

File Concrete Slab Forms Jpg Wikimedia Commons

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

How To Form And Pour A Concrete Slab

How To Form And Pour A Concrete Slab

How To Form And Pour A Concrete Slab Concrete Diy Building A Garage Concrete Slab

How To Form And Pour A Concrete Slab Concrete Diy Building A Garage Concrete Slab

4 Different Concrete Forms And Their Uses By Forming America

4 Different Concrete Forms And Their Uses By Forming America

Part One Preparing The Forms For Concrete Youtube

Part One Preparing The Forms For Concrete Youtube

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

13 Form And Pour A Concrete Slab Ideas Concrete Slab Concrete Slab

13 Form And Pour A Concrete Slab Ideas Concrete Slab Concrete Slab

How To Form And Pour A Concrete Slab Concrete Slab Concrete Diy Concrete

How To Form And Pour A Concrete Slab Concrete Slab Concrete Diy Concrete

/PouringConcreteSlab-715d832fef224f53a859947db1914b16.jpg)

Comments

Post a Comment