- Get link

- X

- Other Apps

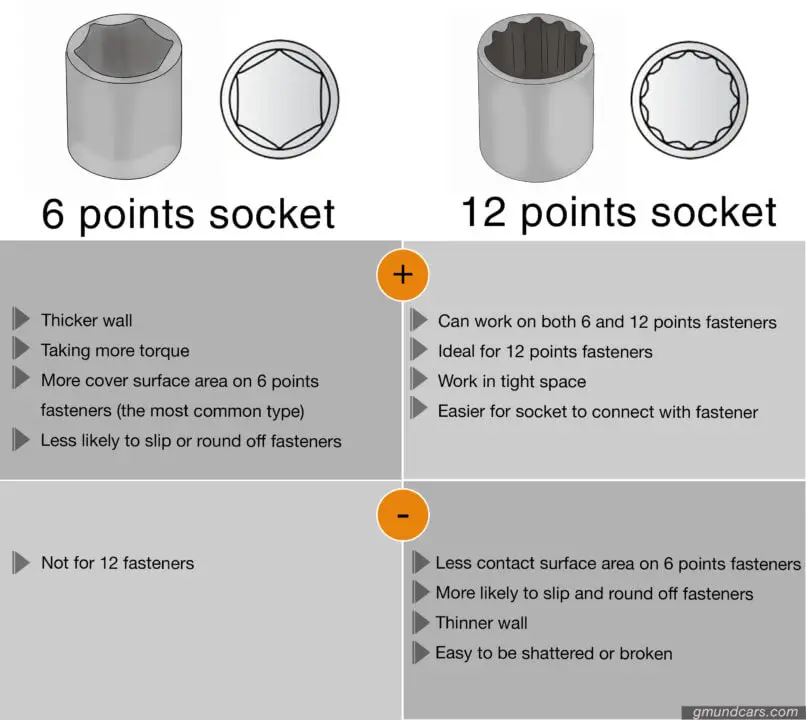

Check prices here And a 12 point socket is going to go over the same nut or bolt in twice as many positions so much easier to use in tight spaces. So the problem of positioning I mentioned as a disadvantage of 6 point sockets isnt an issue here.

Beetle 1958 1967 View Topic Steering Lock And Og Bolts Thesamba Com

Its true that 12-point sockets are fine for most lightweight repairs but heavy wrenching calls for a six-point socket.

6 point vs 12 point sockets. For everyday work they are easier to use. Personally I find myself reaching for the six point sockets most of the time and the twelve point box wrench when I literally have no room to work. Advantages of 12 point sockets.

Both 6-point and 12-point sockets can be fitted on hex nuts the primary differences being convenience and torque. Which should you use 6 point sockets or 12 point sockets. Its a question we get asked all the time.

Bottom line a six point sockets leaves less room for an annoying or costly mistake ie. On the other hand a 12 point socket is double hexagon-shaped including 12 vertices or points. Finally use only sockets made for impact wrenches if at all possiblethey are all 6-point.

However the increment space. Compared with the 6-point socket a 12-point socket has twice as many points so it can more easily slide onto a hex nut. Those are usually not needed.

The additional 6 contact points mean positioning the socket on the fastener is easier. You may have noticed that there are 6-point and 12-point sockets. A 6 point end is hexagonal in shapeit has six points or vertices evenly spaced at 60 degree increments around a circle.

6-point ends typically provide the most precise engagement with fasteners while 12-point ends offer increased access. But what is the real difference. We have both here.

The main difference is that the 6-point socket is built for jobs that require more force. Disadvantages of 12 point sockets. 12 point sockets are fine if you need to make lightweight repairs but for more heavy-duty jobs a 6 point one is better.

It has six vertices or points and they have an even space between them which is 60 angle. 6 point socket debate we prefer six holed sockets because they grip the fastener tightly so there is less chance of sockets breaking or stripped bolts. But 12-points are common to provide a wider range of accessibility and ease of usea lot faster to put a 12-point socket onto a bolt head.

The more points a socket has the more points of contact available. Ideal for jobs that require a large amount of force. As the illustration above shows contact on 6-point fasteners used with a 12-point socket offers less contact area and is more likely to round off the head of the fastener with a lot of force is applied.

Although they accommodate 6 points you should have a 6 hole socket set for better grip. Typically 12-point sockets are more ideal for use in hard-to-reach spaces or areas that cant be seen but can be reached. The answer depends on your tool and situation.

6-point is common for smaller sizes since there is simply not enough surface area contacting the bolt head to apply the needed torque without stripping the head if a 12-point socket were used. No question there. The 6 point sockets are less prone to slippage.

A six-point socket is much less likely to slip off a stubborn fastener or round over the corners. Regular 6-point sockets can be used if absolutely necessary but 12. Additional contact surface along the flat edges of the socket make it.

Well it depends on the job youre looking to do. In the 12 points vs. 6 point socket vs 12 point socket So a 6 point socket is going to go over a standard hex nut or bolt.

Stripped bolt or broken socket and that is why I declare them the winner. One thing I will say for a little 12 point socket especially in a 14 drive dont waste money on anything but Snap-on sockets honestly. Impact sockets pretty much 6 points are mostly whats need although there are exceptions to that too wrenches I hate 6 point box ends pretty much.

A hex nut has 6 points. 12-inch fasteners are pretty rare. A 6-point socket should be used on 6-point fasteners and 12-point sockets on 12-point fasteners.

A six-point socket is of hexagonal shape.

6 Point Sockets Vs 12 Point Sockets Which Should You Use Teng Tools Usa

6 Point Sockets Vs 12 Point Sockets Which Should You Use Teng Tools Usa

Motorcycle Tool Kits Overview Desert Fox Professional Riding Gear

6 Point Vs 12 Point Socket Comparison Youtube

6 Point Vs 12 Point Socket Comparison Youtube

6 Point Or 12 Point The Case For Arp S 12 Point Fasteners

6 Point Or 12 Point The Case For Arp S 12 Point Fasteners

Tip 6 Point Vs 12 Point Sockets Andrew Fixes

Tip 6 Point Vs 12 Point Sockets Andrew Fixes

Hex Points Socket And Twelve Points Socket

12 Point Bolt Socket Cheaper Than Retail Price Buy Clothing Accessories And Lifestyle Products For Women Men

12 Point Bolt Socket Cheaper Than Retail Price Buy Clothing Accessories And Lifestyle Products For Women Men

6 Point Sockets Vs 12 Point Sockets

6 Point Sockets Vs 12 Point Sockets

6 Point Vs 12 Point Vs Spline Drive Youtube

6 Point Vs 12 Point Vs Spline Drive Youtube

A Z Socket Guide Top 10 Socket Sets Review 2021 Gmund Cars

A Z Socket Guide Top 10 Socket Sets Review 2021 Gmund Cars

Lpt Buy 12 Point And Not 6 Point Wrenches And Sockets For Easier Wrenching Lifehacks

Tip 6 Point Vs 12 Point Sockets Andrew Fixes

Tip 6 Point Vs 12 Point Sockets Andrew Fixes

Six Sided Vs Twelve Sided Sockets What S The Difference

Six Sided Vs Twelve Sided Sockets What S The Difference

Comments

Post a Comment